Plastic Material Introduction

Plastics are mainly classified into thermoplastics and thermosetting plastics

Factors affecting the properties of plastic materials

Basically, plastics have a high dependence on temperature, so they respond to temperature. They can be divided into two categories: thermoplastic plastics and thermosetting plastics: Thermoplastic plastics: heat to melt, cool to solidify, and can be repeated. Thermosetting plastics: Once heated to produce cross-chain reaction of molecular bonds and after it is cured and hardened, it will no longer change in temperature and will not melt due to temperature heating.

Influencing the properties of plastic materials, including in its manufacturing process:

Processing temperature

Each plastic has its suitable processing temperature range. If the temperature is too low, it will be difficult to flow and cannot be filled. If the temperature is too high, it may cause thermal cracking. See the YHY blog - Degradation and cracking materials of plastic polymers

Flow velocity

When flowing, different degrees of shear rate will be generated due to the distribution gradient of velocity. If the shear rate is low, the plastic near the skin layer near the mold wall will easily cause stagnation, resulting in difficulty in filling. However, if the velocity is too high If the shear rate caused by the fast is too high, it will cause a high-speed increase in the shear stress, which will cause the sub-bonds of the plastic polymer to be stretched excessively or even torn off, resulting in bond breaking, or excessive frictional heat (produced by viscosity) heat storage effect) and cause thermal cracking of plastics. See the YHY blog - Degradation and cracking materials of plastic polymers

Volume shrinkage

The specific volume change produced during the phase change process can refer to the PVT diagram, which will cause a volume change in the molten plastic. See YHY blog - Design considerations for the thickness of the plastic product and About the post-shrinkage of plastic products

Cooling rate

The molten plastic should be cooled with an appropriate mold temperature. Although the low mold temperature can shorten the molding cycle, if the cooling is too fast, the degree of crystallization will be reduced. To a large extent, it is easy to produce stress residue.

Stress residue

Molecular stretching during flow, excessive pressure during holding pressure, thermal stress and shrinkage stress caused by uneven cooling during cooling, different materials in the process, if the set conditions are not set according to the characteristics of the plastic material , Sometimes the material of the product cracks due to high stress residue or cracks occur after a short period of use by the user.

See YHY blog - About the internal stress of plastic products or Degradation and cracking materials of plastic polymers

Ejection temperature

Each plastic has its appropriate ejection temperature range, and the ejection temperature refers to the temperature of the middle layer of its meat thickness. It must be cooled until the plastic has sufficient rigidity temperature before it will not When it is ejected, it will cause deformation or whitening, and the general choice is below the thermal deformation temperature of the plastic.

YHY BLOG: Talk about the plastic / What is the General plastic?

Thermoplastics are divided into crystalline and amorphous

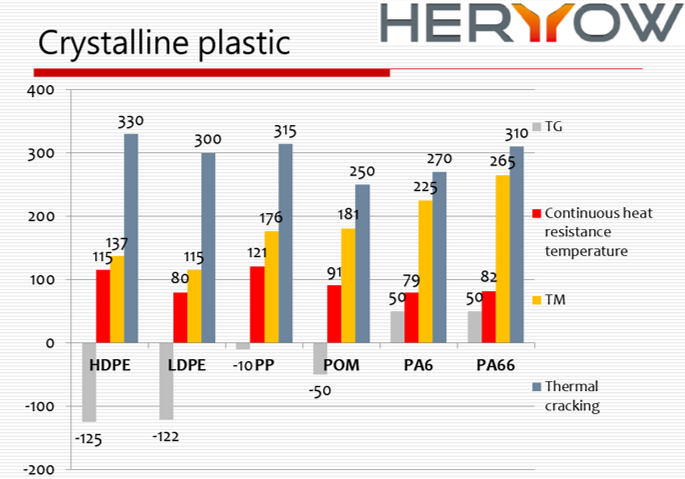

Crystalline plastic

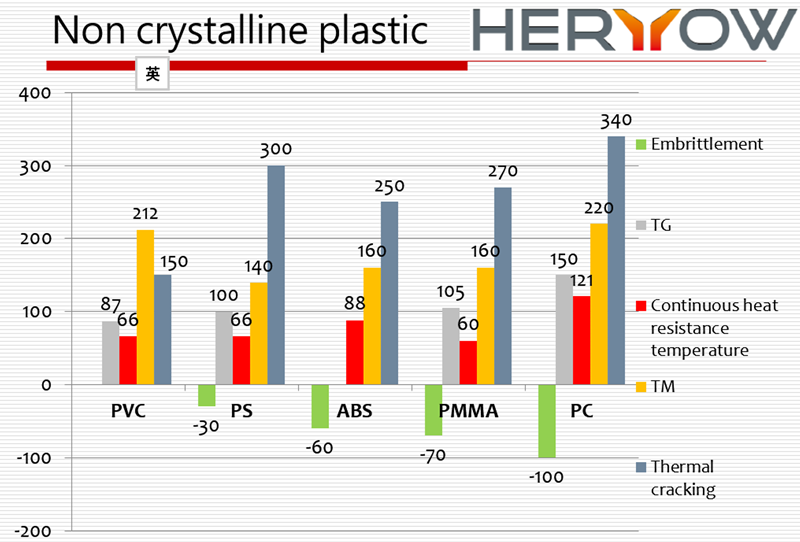

Amorphous plastic

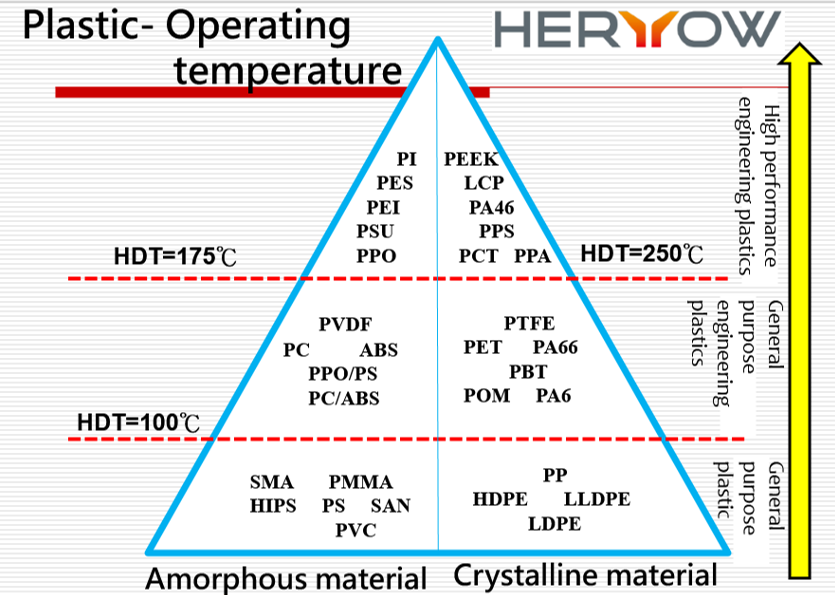

Thermoplastics are divided :

General-purpose plastics

General-purpose engineering plastics

High-performance engineering plastics

-

Sports

Materials:ABS、PMMA、PC、NY66、NY66+PTFE、PBT+PTFE、PPO、POM、TPU、TPR、PP、PPS

-

Kitchen (Flame resistance)

Materials:ABS、PMMA、PC 94V0、NY66+GF、PBT、PP、ABS 94V0、PP 94V0

-

Medical (Anti-bacterial and anti-ultraviolet)

Materials:ABS、HIPS、AS、PMMA、PC

-

Automobile parts (Good high temperature performance)

Materials:PP、ABS、PES、ASA、PBT、POM、PC/ABS、PPO

-

Aerospace (High mechanical strength and excellent balance of stiffness and toughness, good high temperature performance)

Materials:NY66、PPS、PES、PBT、HDPE、PC、ASA

-

Toys

Materials:HIPS、PS、ABS、PMMA、PC、PP、PE

-

Electrical box (Good outdoor resistance: F1/F2, and flame resistance)

Materials:ABS、PC 94V0、PC/ABS 94V0、PBT、NY6+GF、POM

-

Industry and Agriculture

Materials:ABS、ASA、AES、PES、PPS、PC、PMMA、PP

-

Other categories

Materials:PA6T、PA9T、HIPS、PS、PMMA、ABS、PC、PVC、LDPE、HDPE、NY66、PBT、PPO、PEEK

In product development, the selection of materials is a major focus. In the selection of materials and the development process, Yeh Her Yow Plastic Co., Ltd. (YHY) can assist in the development and production. Appearance, use environment, product strength requirements, etc., provide you with the most suitable material selection.