Plastic Material Description and Application (1)

GPPS General Purpose Polystyrene

- Good in transparence and hardness, amorphous resin.

- High rigidity, high surface hardness.

- Poor impact resistance and soft point is relatively lower.

- Good electrical properties and excellent high-frequency properties.

- Good acids/alkalis resistance and hydrolysis resistance, but solvents.

- Emitting black smoke and unique odor as it burns.

- Good adhesion with adhesives.

- Density: 1.01g/cm3

- HDT: 104℃

- Vcat: 102℃

- Applications: Lamp covers, transparent food containers, cassette boxes, large surface but thinness products, and disposable tableware etc.

HIPS High Impact Polystyrene

- Overall properties are similar to PS

- Impact resistance gets worse after reforming.

- Impact resistance is enhanced and transparence property disappears after adding rubbers in PS.

- Density: 1.04~1.10g/cm3

- HDT highest: 99℃

- Applications: Blow-bottle grade food containers, radio shells, TV set cases, computer cases, uses in everyday goods, toys, inside cases of washing machines and inner parts of refrigerator etc.

AS Styrene Acrylonitrile Copolymer SAN

- Transparent and amorphous resin, specific gravity:1.07~1.10.

- Good rigidity, surface hardness, and good surface abrasion resistance.

- Chemical resistance and durability are better than PS.

- Resistance to weak acids, alkalis and oil.

- Heat resistance is better than PS.

- Density: 1.07~1.10g/cm3

- HDT: 94℃

- Tg: 97℃

- Applications: Electrical machine parts, electric fan blades, battery covers, cassette, cases of auto lamps, uses in everyday goods, and stationery appliances etc.

ABS Acrylonitrile Butadiene Styrene

- Amorphous resin without transparence.

- With rigidness and good mechanical properties.

- Bad heat resistance but good processability.

- Excellent electrical properties and good surface luster.

- Little molding shrinkage, good creep resistance.

- Strength is decreased after long term sun-light exposure.

- Resistance to acids, alkalis but melting in solvents.

- Emitting black smoke and funk as it burns.

- Density: 1.04g/cm3

- HDT: 95℃

- Vcat: 106℃

- Applications: Electrical parts, radio shells, mechanical structures, metallic-looking items, auto panels, display cases, pipes, stationery, containers, suction parts, safety helmets, and battery cases etc.

PMMA Polymethyl Methacrylate

- Excellent transparence and good durability.

- High hardness and excellent surface luster.

- Resistance to water, salt, and weak acid, but poor to alkalis and organic solvents.

- Good molding properties.

- Deformed at 100℃, bad impact resistance.

- Exceptional electrical properties.

- Density: 1.20g/cm3

- HDT: 68~99℃

- Vcat: 110℃

- Applications: Lamp parts, transparent panels, windshield glass, tail lamps, advertising lamps, lamp bases, advertising signs, buttons, other decorative items, glasses, false teeth, optical parts, and medical goods etc.

CA Cellulose Acetate

- Crystalline resin, great durability.

- Antistatic and dustproof.

- Transparence, non-toxicity, and great impact resistance.

- Density: 1.30g/cm3

- Tg: 120℃

- Applications: Radio shells, telephones, auto steering wheels, electric fan blades, coatings, photographic film, audio tapes, stationery, fireproof items, and spectacle frames etc.

PA66/NY66 Polyamide 66

- Tough engineering plastic with excellent impact resistance.

- High surface hardness, low friction coefficient, having self-lubricating ability.

- Exceptional electrical properties at low temperatures, having self-extinguishing ability.

- Excellent chemical resistance and oil resistance.

- High water absorption, mechanical properties is changeable with its size.

- Density: 1.14g/cm3

- HDT: 66~104℃

- Tm: 265℃

- Tg: 50℃

- Applications: Electrical & mechanical parts, pipe materials, films, vehicle parts, and zippers etc.

PA6/NY6 Polyamide 6

- Physical properties are similar to PA66.

- PA66 has higher flexural strength, hardness, abrasion resistance, and heat resistance than PA6

- PA6 has better impact resistance and shrinkage is smaller than PA66.

- Density: 1.14g/cm3

- HDT: 66~79℃

- Tm: 225℃

- Tg: 50℃

- Applications: Electrical & mechanical parts, pipe materials, films, vehicle parts, and zippers etc.

PBT Polybutylene Terephthalate

- Melting temperature 224℃ is lower than PET, and as tough as PET in ambient temperature.

- PBT toughness can reach certain level without fiber reinforcement as PET, and PBT can Process with films, mono foliations, sheets, and fibers.

- Exceptional fatigue and heat resistance.

- Great abrasion resistance and self-lubricating ability.

- Easier molding, lower absorption, better acid and oil resistance than PET.

- Good electrical properties and good durability.

- Poor hot water and alkalis resistance.

- Density: 1.31g/cm3

- HDT: 59℃

- Tm: 225℃

- Tg: 30 ℃

- Applications: Vehicle parts( auto parts, seat belts, gear wheels, office machinery, sewing machine components, camera, clock shells), electrical parts (connectors, electrical tools, switches, cases), architecture materials, and containers etc.

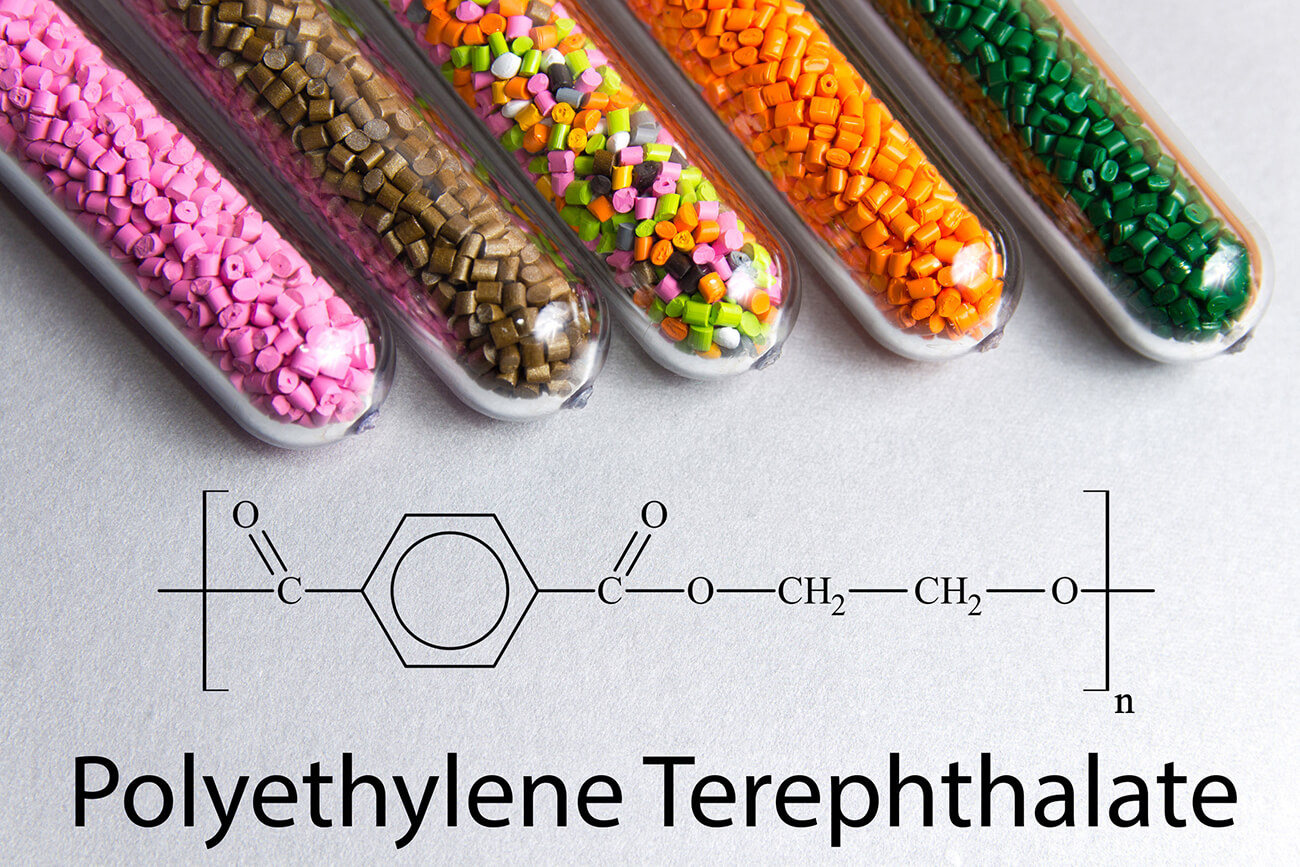

PET Polyethylene Terephthalate

- Toughness, getting higher strength through heating.

- Great heat and creep resistance, excellent electrical properties.

- Good durability, bi-axially expanded film is good in transparency.

- Good organic solvent and oil resistance, good weak acid resistance.

- Non-toxicity, low water absorption, poor resistance to hot water and alkalis.

- Density: 1.34g/cm3

- HDT: 76℃

- Tm: 260℃

- Tg: 70℃

- Applications: Electrical components, PET bottles, and films(tapes, insulating films, and packaging films).

In product development, the selection of materials is a major focus. In the selection of materials and the development process, Yeh Her Yow Plastic Co., Ltd. (YHY) can assist in the development and production. Appearance, use environment, product strength requirements, etc., provide you with the most suitable material selection.