Manufacturing Capacity

Production Capacity

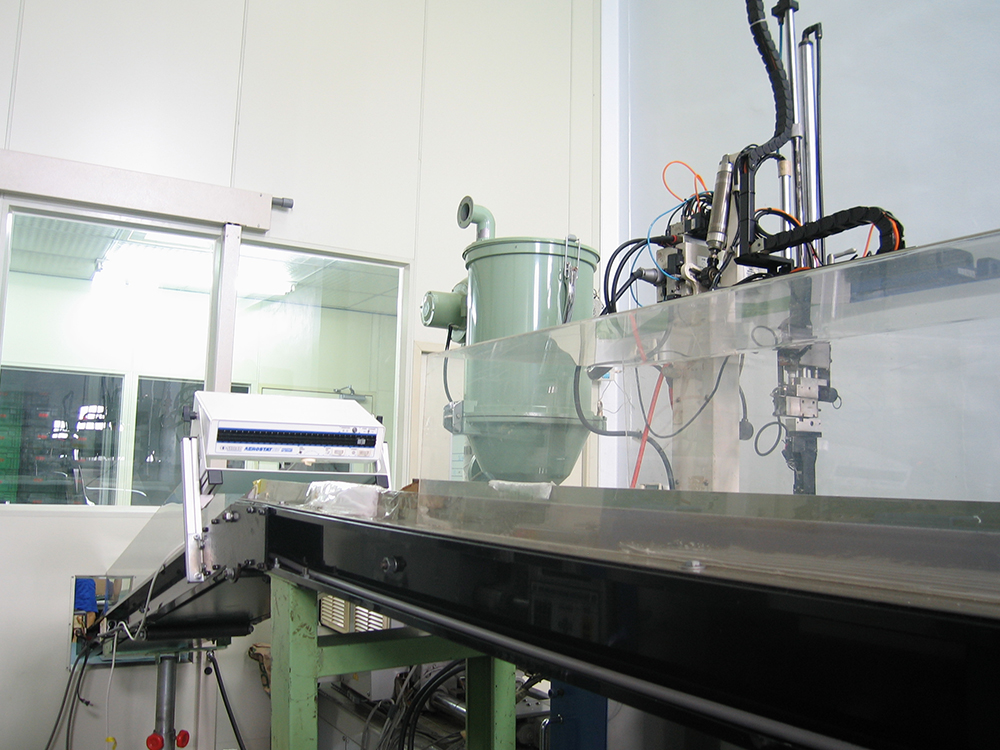

Yeh Her Yow Plastic Co. Mfg. Ltd. owns 22 plastic injection machines ranging from 100 tons to 2500 tons. These machines are capable of producing items as small as 5mm to as large as 1.2m. The weight of the product can reach nearly 5 kg. In the disassembly of the product, all the product parts of the product can be handed over to Yeh Her Yow Company. In addition, among the injection machines of the same tonnage, the specifications of the machine equipment are matched. In response to different plastic materials, it can be mass-produced more in line with the characteristics of the material, maintain higher physical properties, and avoid many secondary processes (such as painting, printing, electroplating, coating, etc.) in the post-processing process. , lock payment assembly, etc.), during the mold development, assist customers to develop and design plastic materials for injection of various general-purpose plastic materials, engineering plastic materials, high-performance engineering plastic materials and special additives or applications with mold. All plastic injection molding machines are equipped with mechanical arms, which can improve automation efficiency, and the high-efficiency production mode can cope with a large number of production modes for customers. Second, it can stabilize the production mode, greatly reduce the defect rate, and ensure the quality of customers. . More than a dozen mold heating machines, including water temperature machines for cleaning and oil temperature machines for ultra-high mold temperature requirements for special needs, can greatly stabilize and maintain the mold temperature control of the production cycle, and accurately maintain the production quality at the most precise scope.

| Machinery and equipment | Quantity |

|---|---|

| 100 T - Injection machine | 1 |

| 120 T - Injection machine | 1 |

| 150 T - Injection machine | 2 |

| 180 T - Injection machine | 1 |

| 220 T - Injection machine | 1 |

| 250 T - Injection machine | 4 |

| 350 T - Injection machine | 3 |

| 450 T - Injection machine | 3 |

| 600 T - Injection machine | 2 |

| 750 T - Injection machine | 1 |

| 1000 T- Injection machine | 1 |

| 1300 T- Injection machine | 1 |

| 1500 T- Injection machine | 1 |

| 2500 T- Injection machine | 1 |

| Machinery and equipment | Quantity |

|---|---|

| Oil temperature machine | 5 |

| Freezer | 2 |

| Water temperature machine | 12 |

| Dehumidification dryer | 6 |

| Hot runner controller | 8 |

Enhanced Robotics

Each plastic injection machine is equipped with a robotic arm for enhanced automation efficiency. Robotic automation assures consistent, high-quality products, rapid and consistent production cycle times, and reduced labor costs.

Smart Production

Internet of Machines + Smart Production

- Intelligent networking of equipment + construction of big data, towards the construction of smart factories

- Production efficiency improvement

- Continuous improvement of product quality

- Realize two-way quality traceability

- Achieve lean production

- Realize production transparency

- Improve production execution capabilities

Extensive Processing Ability

- Precision: Tolerances can be consistently maintained to within 0.01 mm.

- Capacity: Molds can be made for products as small as 0.5g to as large as 15kg.

- Material: General-purpose plastic, such as ABS, PP, PS, PE, PMMA, ASA, AS, and CA. Engineering plastics, such as PC, POM, PBT, PA, PA6, PA66, PES, PPO, PTFE, TPR, TPU, and PES.

- Application industries: Automobile, motorcycle, kitchenware, sports equipment, electronic parts, electrical boxes, medical equipment, toys, aviation, etc.

Rapid Fulfillment of High-volume Orders

24H production and plastic injection machines with vast production capabilities assure high production capacity. Our injection technicians cooperate with the Plastics Industry Development Center (PIDC) and have passed the National Certification Examination.

Customized Service

Customized services, including the application of additives, fireproof materials, antibacterial materials, antioxidant materials, weather-resistant materials, anti-UV materials, structural reinforcement additives (glass fiber, mica, talc, etc.), wear-resistant PTFE additives, and color additives (pearl powder, silver powder, etc.) are all available.

Our business plan offers flexibility to our customers to ensure that products are designed accurately and fit our customers’ needs. Our goal is to provide exceptional quality & service at a reduced cost.

Product Post-processing

Product post-processing offered by YHY includes, printing, thermal transfer, baking varnish, ultrasonic welding, ultrasonic metal embedding, and product assembly. We have experience working with various fields that require specialized post-processing and can offer solutions to bring your products to completion.

Contact Us

We welcome you to learn more about our plastic injection capabilities. Contact us and we will be happy to discuss details of cooperation with you.