Plastic Material Description and Application (3)

BT Bismaleimide Triazine

- Good heat resistance and adhesion to the board

- Can meet the needs of high-speed transmission circuit boards

- Can prevent leakage phenomenon

CE Cyanate Ester

- Pure cyanate has a dielectric constant of 2.8

- With different reinforcing fibers, it can be made into substrates with different dielectric constants. When reinforced with quartz fibers, the dielectric constant value can be as low as 3.1

EP Eposy Resin

- High metal adhesion and good chemical resistance

- High mechanical strength and good insulation

- The traditional epoxy resin is called double palace energy-based epoxy resin, and it will continue to burn after fire until the carbon, hydrogen and oxygen in the polymer are burned out

ETFE Ethylene Tetrafluoroethylene

- It is a kind of thermoplastic fluororesin with high shrinkage

- Good electrical properties, excellent insulating material, very low dielectric constant

- Good heat resistance, flame resistance, oxygen index 95%, UL 94V0, is a stable flame resistance substance that can be used for many different purposes

- Excellent chemical resistance, almost no reaction to all chemicals, good chemical resistance

- High mechanical strength, low friction, low viscosity

- Excellent weather resistance, no loss or deformation when directly exposed to sunlight, rain or exhaust gas, and long-term exposure to outdoor characteristics without adding GF and CF to increase its vibration resistance

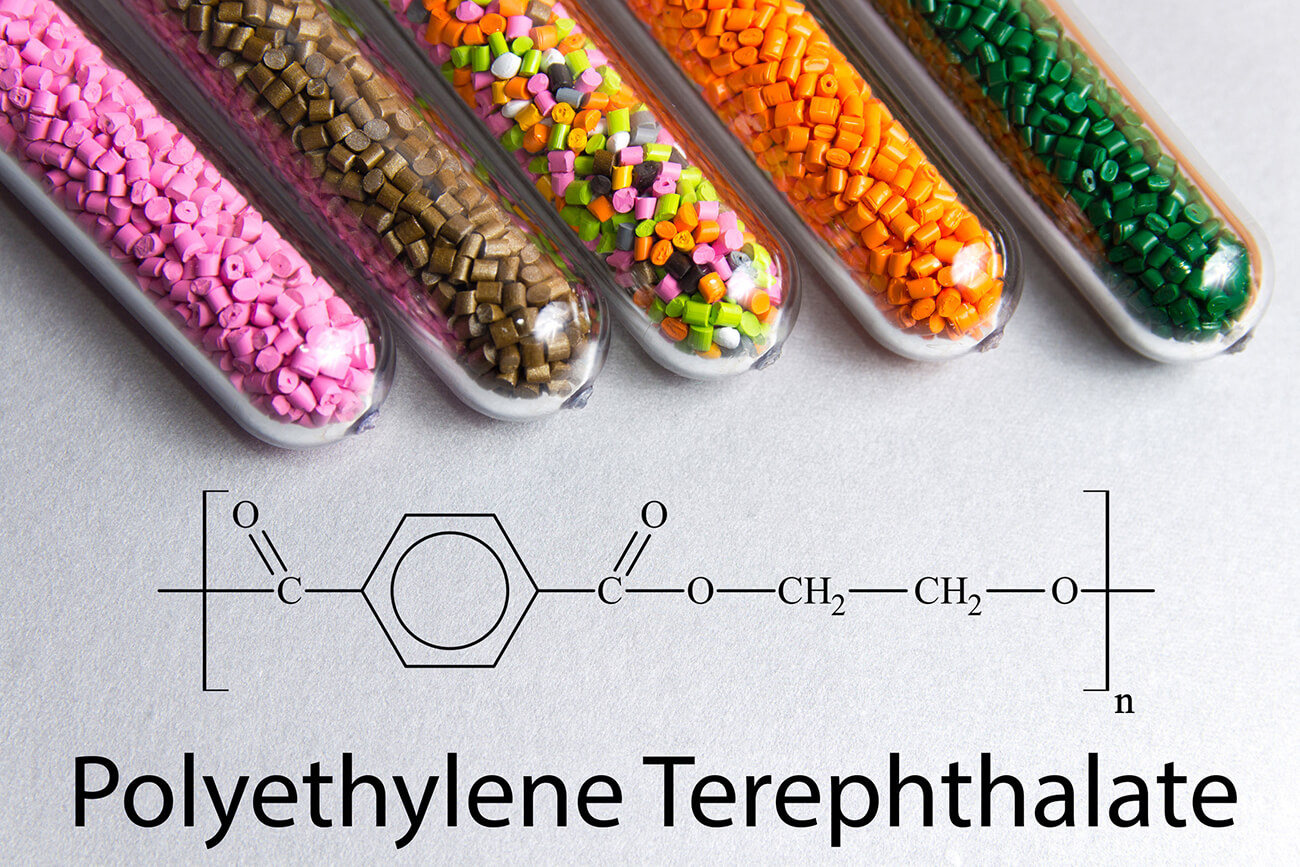

FR-PET Strength Polybutylene Terephthalate

- Excellent electrical properties, good weather resistance, excellent mechanical properties, small Creep

- Fast crystallization speed, excellent formability, good fluidity

- Good heat resistance, better heat resistance than FR-PBT

- Resistant to organic solvents, oils, weak acids

- Good surface gloss and good colorability

MF Melamine Fomraldehyde

- Same as UF, only water-resistant surface hardness

- Flame resistant, colorless, easy to color

M-PPE Modified Polyoxyxylene Resin

- Good processing stability and small forming shrinkage

- Excellent mechanical properties, good heat resistance and water resistance

- Self-extinguishing and fire-resistant

- Good electrical properties but poor chemical resistance

LCP I Liquid Crystal Polymer Type I

- Among the three LCP types, the heat resistance is the highest

- Good chemical resistance, dimensional stability and self-lubrication

- Flexural strength, deterioration in highly concentrated alkali vapors

- Large anisotropy, high temperature molding, high price

LCP II Liquid Crystal Polymer Type II

- Good chemical resistance, high fluidity, vibration absorption properties and good mechanical strength

- Low longitudinal expansion coefficient

- Poor bending strength and large anisotropy

- Strength is greatly affected by thickness

- Unfilled grades are prone to surface peeling

LCP III Liquid Crystal Polymer Type III

- Good chemical resistance, high fluidity, vibration absorbing properties and good formability

- Poor bending strength and large anisotropy

PAI Polymide Imide

- High strength and hardness

- Flame retardant, UL 94V0, good weather resistance

- Excellent chemical resistance, hot water resistance, good heat resistance, excellent creep resistance

- Excellent electrical properties, easy molding, good dimensional stability

- Small change in elastic coefficient below 260°C

- Poor formability, fluidity, alkali resistance and hygroscopicity

- expensive

PAR Polyarylate, U-Polymer

- Good organic, colorless and transparent

- Temperature resistance and HDT are above 150℃, good impact resistance at low temperature, high impact strength, small dependence on thickness

- Nonflammable, Oxygen Index 36.8, UL 94V0

- Good weather resistance, UV resistance and electrical properties

- Good latent resistance at high temperature

- Poor solvent resistance, acid and alkali resistance and poor fluidity

PEEK Polyether Ether Ketone (Polyether Ether Ketone)

- Temperature resistance, good thermal stability, ultra-high heat resistance (better than PPS), HDT above 315°C, UL continuous use temperature of 250°C

- High mechanical strength such as impact resistance, wear resistance, creep resistance and fatigue resistance

- Chemical resistance (except concentrated sulfuric acid), best hot water resistance (PPS, PES or higher)

- Good resistance to gamma rays, flame retardancy, extrusion processability, minimal smoke generation, and radiation resistance

- Excellent electrical characteristics under high temperature and high humidity

- High toughness, good mechanical strength and rigidity, poor workability

- Good flame resistance, no need to add flame retardant

- High price, high temperature molding, extremely poor fluidity

PEI Polyetherimide

- Used for injection molding, with the highest tensile strength

- The best latent resistance (room temperature ~ 150 ℃), the elastic coefficient changes little below 150 ℃

- Flame retardant, UL 94V0, oxygen consumption index 42, good flame resistance and weather resistance, less smoke, high transparency

- Excellent wear resistance, temperature resistance, oil resistance and chemical resistance

- High temperature molding is required, poor fluidity, alkali resistance and moisture absorption

PES/PESF Polyether Sulfone

- Use ambient temperature -100℃~170℃, good mechanical strength, temperature resistance, small change of elastic coefficient below 180℃

- Good dimensional stability and high transparency

- Resistant to high temperature water vapor, hot water and acid and alkali, with excellent high temperature latent properties

- High oxygen consumption index, UL 94V0, flame retardant, less smoke

- Excellent electrical characteristics

- Poor solvent resistance and weather resistance, requiring high temperature to form

PFA Tetrafluoroethylene-Perfluoroalkoxyethylene

- A kind of thermoplastic fluororesin

- Good electrical properties: excellent insulating material with very low dielectric constant and very low dielectric dissipation factor

- Heat resistance, wide operating temperature range, -200℃~280℃

- Flame resistance, oxygen index 95%, is a kind of stable material, can be used for different purposes

- Excellent chemical resistance, almost no reaction to all chemicals

- high mechanical strength

- Low surface energy, low friction, low non-stickiness, and high surface water and oil repellency to water and oil, which can increase the reliability of raw materials

- Excellent weather resistance, no loss or change in direct exposure to sunlight, ultraviolet light, water or waste, no change in long-term exposure to outdoor characteristics

- Good chemical resistance, low coefficient of friction, non-adhesive

- Poor formability, large shrinkage, and high price

PI Polyimide

- High heat resistance, little change in elastic modulus below 240°C

- Excellent wear resistance, creep resistance and radiation resistance

- Excellent chemical resistance, except concentrated nitric acid, but not strong acid resistance

- Difficulty in injection and extrusion, high crystallization temperature

- The dimensional change is small, and the thermal expansion coefficient in the X and Y directions is very small, which can avoid the poor adhesion of the copper foil caused by the heat of the thin circuit. The copper layer is thermally fractured

PVA Polyvinyl Alcohol

- Colorless transparent elastomer

- good heat resistance

- High insulation softening point

PVAC Polyvinyl Acetate

- Colorless and transparent

- Good adhesion and light resistance

- Poor heat resistance

- High water absorption, most solvents are soluble

PVDC Polyvinylindene Chloride

- Better chemical resistance than PVC

- good heat resistance

- The air permeability of the film is low

TPE/TPR Thermoplastic Elastomers/Thermoplastic Rubber

- Soft, elastic, good touch

- Simple, fast and recyclable processing

In product development, the selection of materials is a major focus. In the selection of materials and the development process, Yeh Her Yow Plastic Co., Ltd. (YHY) can assist in the development and production. Appearance, use environment, product strength requirements, etc., provide you with the most suitable material selection.