Diverse Technologies of Plastic Surface Treatment: One-stop Processing Services to Enhance Product Appearance

In the field of plastic product processing, Yeh Her Yow plastic Co., Ltd. provides one-stop services from plastic injection molding to surface decoration with its profound technology and complete equipment. We are good at various complex appearances and high-quality decoration technologies, including water transfer printing, in-mold decoration (IMD), electroplating, painting and diversified printing and engraving processes.

Through integrated process configuration and professional quality control management, we can effectively help customers accelerate development schedules, improve product stability and appearance texture, and achieve the final result of both appearance and function.

The following will introduce various plastic surface decoration technologies and common adverse phenomena to help you gain a deeper understanding of the technical key and quality control points of the decoration process:

The following will introduce various plastic surface decoration technologies and common adverse phenomena to help you gain a deeper understanding of the technical key and quality control points of the decoration process:

Water transfer printing is suitable for irregular or multi-dimensional decorations. The process includes:

- Printing the pattern on a thin film attached to a carrier.

- Placing the carrier on the water bath surface and spraying a solvent to dissolve the carrier, allowing the film to float on the water.

- Immersing the injection-molded part into the water, where the decorative film adheres to the part.

- After drying, a clear coat is applied to enhance wear resistance and visual depth.

Defects in Water Transfer Printing Process

Water transfer printing, while effective for decorating irregular or multi-dimensional surfaces, can encounter several defects during the process. Below are some common issues and their potential causes:

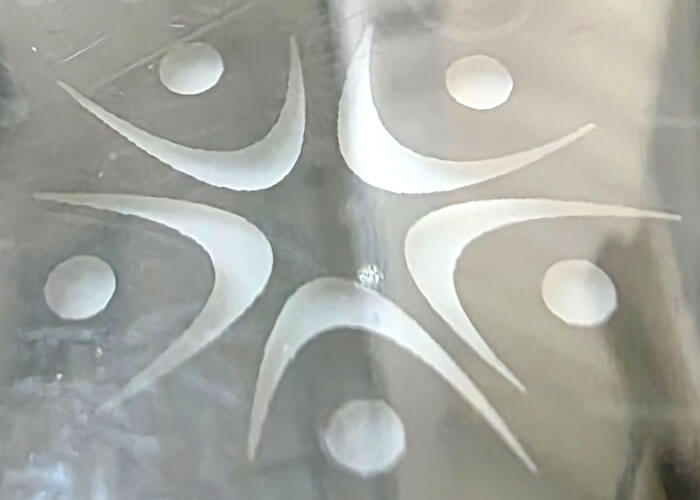

- Fish Scale Type Melt Disturbance

This defect appears as high-frequency smaller waves that resemble fish scales or arrowheads. It is typically due to exceeding a critical shear stress for the coextruded polymer pair in the final die land. - Degradation Products

Degradation products can contaminate the final product, leading to diminished physical properties. This occurs when there are regions in the process where the flow is stagnant or over-shear, allowing the resin to degrade via oxidation and temperature. - Surface Defects

Surface defects such as specks, burn marks, fisheyes, coating tears, streaks, and flow lines can occur. These defects can be caused by various factors, including improper machine settings, contamination, or material incompatibility. - Flow Marks and Texture Variation

Flow marks and texture variations can appear on the plastic decorated surface. These issues can arise due to local burning or degradation of the plastic, pigment or additive separation, inadequate homogenization, or contaminants in the material.

By understanding and addressing these common defects, the quality and consistency of the water transfer printing process can be significantly improved, you can ask the professional Yeh Her Yow plastic Co., Ltd. to serve you.

In-Mold Decoration (IMD): Achieve exquisite appearance and structural integration

In-mold decoration combines high-quality decorative surfaces (such as special decorative films or decorative textiles, wood grain, etc.) with plastic materials. The process involves:

- Inserting the decorative surface (film) into the mold, which deforms when the mold closes.

- The decorative surface is then IMD with the plastic material.

- Material and process selection must ensure the decorative surface remains undamaged (e.g., film melting or textile burn-through).

- After cooling and demolding, final trimming is performed.

Defects in Back Injection Molding Technology

Back injection molding technology is crucial for plastic surface decoration, but several defects can arise during the process. Below are some common issues, their potential causes, and solutions:

- Incomplete Filling

The part is not fully filled, resulting in short shots. - Surface Defects

Surface defects such as specks, burn marks, fisheyes, coating tears, streaks, and flow lines. - Weld Lines

Weld lines are linear defects formed when two flow fronts meet in the mold. - Warping

The part deforms during the demolding process. - Dimensional Issues

The part dimensions do not meet specifications.

The above are common defects. There are many causes of these defects. Improving the yield rate and reducing the defect rate can make the products more competitive in the market. If you have related process needs, please contact Yeh Her Yow plastic Co., Ltd.

Electroplating: Metal appearance and improved durability

Electroplating imparts conductivity or a metallic appearance to plastic surfaces. The process includes:

- Mechanically blasting or chemically etching the plastic surface to roughen and polarize it.

- Treated surfaces can be nucleated with ruthenium compounds, which are conductive and allow the deposition of conductive metals (typically copper or nickel).

- The primary goal of electroplating is to make plastic parts appear like polished metal parts.

Defects in Electroplating Process

Electroplating is a widely used technique to impart conductivity or a metallic appearance to plastic surfaces. However, several defects can arise during the electroplating process. Below are some common issues, their potential causes, and solutions:

- Cracking

Fine network of cracks appears on the plated surface. This is often due to the formation of free hydrogen during deposition, which can be temporarily stored as chromium hydride in the layer. Over time, the hydrogen is released, leading to a decrease in volume and the formation of residual tensile stresses, which then dissipate via a fine crack network. - Pitting Corrosion

Small, localized corrosion spots that penetrate deeply into the material. Variations in the electrochemical potential on the surface due to microalloying elements can lead to pitting corrosion. If the oxygen passivation is broken locally, high current flows and erosion rates occur at the relevant defects. - Surface Defects

Defects such as specks, burn marks, fisheyes, coating tears, streaks, and flow lines on the plated surface. These defects can be caused by improper machine settings, contamination, or material incompatibility. - Poor Adhesion

The plated layer does not adhere properly to the substrate, leading to peeling or flaking. Poor surface preparation, contamination, or incorrect plating parameters can lead to poor adhesion. - Hydrogen Embrittlement

The plated part becomes brittle and prone to cracking. Hydrogen atoms can diffuse into the metal during electroplating, leading to embrittlement. - Discoloration

The plated surface exhibits uneven or undesired colors. Discoloration can result from contamination in the plating bath, improper plating parameters, or post-plating oxidation.

The above are common defects. There are many causes of these defects. Improving the yield rate and reducing the defect rate can make the products more competitive in the market. If you have related process needs, please contact Yeh Her Yow plastic Co., Ltd.

Painting

Painting enhances the scratch resistance and visual appeal of plastic parts. The process includes:

- Plastic parts are painted to change the color or weather resistance of the surface.

- Industrial painting systems are divided into organic and inorganic systems, chosen based on technical requirements and cost.

- If temperature limits cannot be exceeded, UV-curable coatings are preferred.

Defects in Painting Process

Painting is a widely used technique for decorating plastic parts, but several defects can arise during the process. Below are some common issues, their potential causes, and solutions:

- Silver Streaks (Partly Over the Surface) Silver streaks starting from the gate indicate too high shear.

- Dents Dents appear on the surface.

- Delamination Delamination of material occurs on the plastic surface, forming a film or peeling on the surface of the component.

- Color Streaks Color streaks occur when the material is contaminated or there is a mixing or degradation issue, this undesirable phenomenon is usually observed in plastic materials.

The above are common defects. There are many causes of these defects. Improving the yield rate and reducing the defect rate can make the products more competitive in the market. If you have related process needs, please contact Yeh Her Yow plastic Co., Ltd.

Printing Techniques

Printing techniques include pad printing, screen printing, and laser etching, used to add patterns or logos to plastic parts.

These techniques and processes can be combined and applied according to specific needs to achieve diverse decorative effects on plastic surfaces.

Printing processes for plastic components involve various techniques to add labels, instructions, or decorative patterns to the surface. Below are some common printing methods and their applications:

Screen Printing: Application of traditional crafts in modern plastic products

Screen printing is an ancient printing method invented by the Chinese over 2000 years ago. The process involves the following key steps:

- Stencil Preparation: A stencil carrying the desired printing pattern is created. This stencil is placed on a finely woven fabric screen.

- Ink Application: The areas of the fabric where no ink is to be printed are made impermeable by the stencil. Ink is then pressed through the permeable areas of the screen.

- Transfer to Surface: The screen is placed against the plastic surface, and the ink is transferred onto the surface through the permeable areas of the stencil, creating the print.

Laser Engraving: Precision processing technology for diverse materials

Laser engraving is a precise technique that uses a focused laser beam to etch or mark the surface of various materials, including plastics, metals, ceramics, and hard metals. Below is a detailed description of the laser engraving process:

- Laser Beam Focusing: Laser engraving uses a focused laser beam to concentrate energy on a small spot on the material's surface.

- Material Removal: The energy from the laser beam is absorbed by the material's surface, converting it into heat, which vaporizes or melts the material to create the engraved pattern.

- Control System: The engraving pattern is usually designed on a computer and controlled by a numerical control (NC) system that directs the laser beam's movement and energy output to achieve precise engraving.

Heat Transfer Printing: Gold platinum or silver platinum printing and embossing technology

Heat transfer printing is a technique used to transfer patterns from a specially prepared transfer film onto the surface of plastic products. This process involves using heat and pressure to ensure the pattern adheres properly to the plastic surface. Below is a detailed description of the heat transfer printing process:

- Preparation of Transfer Film: The transfer film is prepared with the desired pattern. The film typically consists of a carrier film, a release layer, a pattern layer, and an adhesive layer.

- Heating the Stamping Tool: The stamping tool is heated to the required temperature.

- Pressing: The transfer film is placed on the plastic surface, and the heated stamping tool applies pressure, causing the pattern to transfer from the film to the plastic surface.

- Cooling and Peeling: After cooling, the transfer film is peeled away, leaving the pattern adhered to the plastic surface.

Contact us now to explore customized decoration solutions

Whether you are pursuing high-end texture of product appearance or industrial-grade quality that requires durability, Yeh Her Yow plastic Co., Ltd. can provide professional and diverse plastic surface treatment technologies. We are committed to helping customers stand out in the fiercely competitive market. From design and proofing to mass production, every step is strictly controlled to ensure the delivery of stable quality and exquisite appearance of the final product. If you have any needs or technical questions about the plastic surface decoration process, please contact us. We will provide the most professional one-stop service and technical support to work together to create more competitive products.