5 Key Points in Plastic Injection Molding Product Design | Core Factors Affecting Cost and Quality

Why does product design have a huge impact on injection molding cost and quality?

During the product development process, design is not only related to the actual appearance and function of the product but also affects the manufacturability of injection molding. An efficient design can reduce the difficulty of mold development, reduce material waste, shorten the seed production cycle, and avoid molding defects and quality problems.

What factors will affect the cost of injection molding?

1. Design factors that affect the cost of injection molding

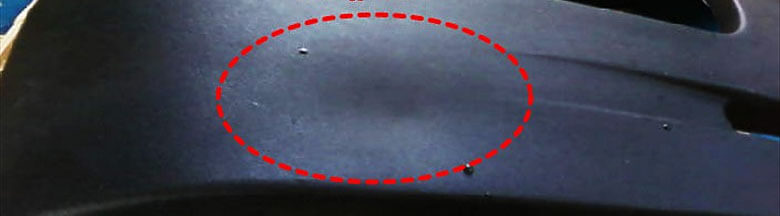

The product's geometry, wall thickness, support, rib structure and other factors directly determine the mold design and production cost of injection molding. Among them, appropriate "wall thickness" design can avoid uneven change in speed, beach molding or inhalation disease, and cracks on the bottom.

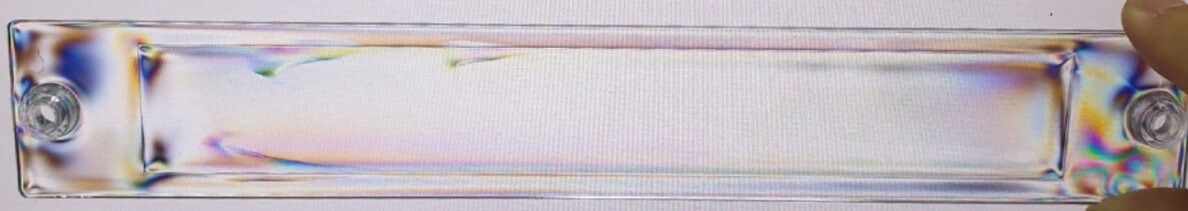

Well thickness

Make the plastic flow evenly and avoid molding defects. The size of the product will affect its reasonable thickness. Different materials also have their appropriate thickness. The shape and curvature of the product will also affect the reasonable thickness. How to avoid insufficient product strength or excessive material caused by excessive wall thickness? Appropriate wall thickness can ensure product strength, but too thick will increase material cost and cooling time, too thin may cause deformation or cracking. How to design structures such as Boss columns, ribs, positioning columns, and partition walls will affect mold design and cost. Therefore, the design of wall thickness/product thickness is important.

Learn More: Design considerations for the thickness of the plastic

In addition, the following design factors are also closely related to cost:

Smoothness of turning

Reducing stress concentration, improving product durability, and gaining a deep understanding of how plastics flow and pressure are transmitted can help you add a reasonable transition concept to your product design, which will result in a 1+1>2 effect. However, if the design is insufficient or excessive, it may result in a 1+1<1 effect="" p="">

Support structure

Through ribs or reinforcement design, the rigidity of the product can be improved, the material usage can be reduced, and the mold cost can be reduced. The design of ribs is not the more the better, nor the less the better. How to make a reasonable design based on the actual needs of the product can achieve the best effect.

Draft Angle

The appropriate draft angle can ensure the smooth demolding of the product and reduce the risk of damage during the production process. Insufficient angle will cause demolding problems, and other types of mechanisms will be required to cooperate, resulting in additional mold development costs. However, too large a draft angle may deviate from the product design type, and more components will be required for modification.

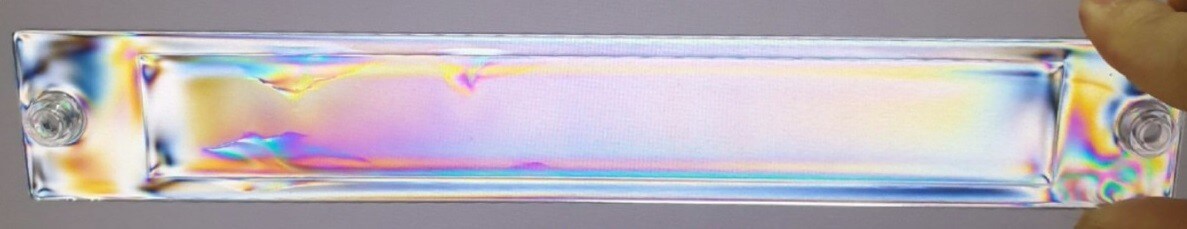

Stress distribution

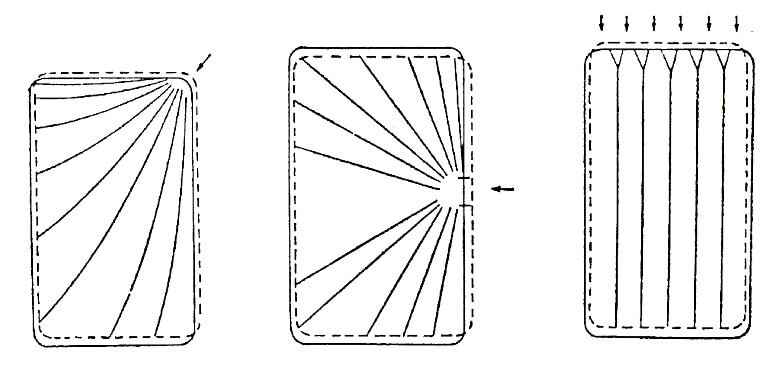

How to deeply analyze the flow of plastic during molding, reasonably design the runners and gates, and make reasonable optimization based on the product structure can reduce excessive stress concentration in a certain place. Without good stress analysis to do the design, it often takes a higher cost to improve later.

Related articles: About the internal stress of plastic products

2. The negative impact of material selection on molding

When deciding which plastic material to use, such as ABS, PP, PC, PA, PBT, PMMA, PE, PS, PVDC, PCT, PCG, etc., the design side needs to consider the product use environment to achieve the best performance:

- Temperature resistance requirements – Some products are used in relatively high temperatures, even up to 200~300°C.

- Surface gloss or texture requirements – The requirements for exterior products and internal structural parts are different, and there will be different visual feelings.

- Heat resistance and impact resistance requirements – Meet the use requirements of product use scenarios

- Folding and bending resistance requirements – Some structural products have folding or bending strength requirements

- Fire and flame retardant applications – Special application scenarios require fire and flame retardant requirements

- Surface treatment feasibility – Affects the quality of post-processing such as spraying and laser engraving

- Environmental protection and recyclability – Meet the sustainable development standards of modern enterprises

In addition to functionality, it is also necessary to consider whether UL heat resistance rating requirements are required.

3. Relation with Mold design and structural: parts coordination to reduce costs

In injection molding, the design of the product must meet the mold manufacturing standards to ensure the conditions of manufacturing and quality:

- Excellent product parting surface design – ensure molding integrity, appearance focus, demolding starting position and forward and reverse break differences.

- Appropriate male and female mold cooling design – Excellent design can greatly avoid product warping and deformation during the process, and can effectively improve production efficiency, thereby reducing production costs. If the design is poor, problems such as appearance dents, warping, extended production cycles, and large dimensional variations often occur.

- Appropriate common component design and structural secondary processing – reduce assembly steps through reasonable design, and improve overall production efficiency and reduce energy consumption and costs through reasonable combined component design, component common mold, and mold structure improvement.

4. Use mold flow analysis and precision injection technology to prevent molding problems

In plastic injection molding, product design cannot be done alone. If the molding process and mass production conditions are not included, the design may be ideal but cannot be produced, resulting in unnecessary waste of development costs. Therefore, from the early stage of design, DFM (Design for Manufacturability), mold flow analysis and precision mold technology should be combined to ensure that the product has good injectability and mass production stability.

- DFM – Make the design more suitable for mass production and improve feasibility

- Mold flow analysis – Through multi-dimensional simulation prediction, and accurately confirm the flow path of the molten plastic, to ensure that the material can reach the microstructure details of all mold surfaces, and improve the transfer rate of surface microstructures.

- Precision mold design – Through high-precision CNC machining and EDM technology, the mold can be molded with extremely small details, such as fine textures, thin-walled structures, etc., and the parameters of injection molding are taken into consideration to optimize the precision of precision molds.

- Injection molding parameter adjustment – injection pressure, injection speed, injection position, holding pressure, holding speed, holding time, material tube temperature, mold temperature, material storage/feeding speed, back pressure and cooling time, etc., and even in the conditions of mold opening and ejection methods, how to optimize the parameters to achieve the highest yield, so that the molten plastic material can evenly fill the mold during molding, avoiding defects such as flow marks, shrinkage marks, spray marks, air marks, and bubbles.

- High-precision measurement and quality control – Through various tool measurements, ensure that each finished product meets the dimensional accuracy requirements.

Yeh Her Yow plastic Co., Ltd. service material application expertise

Our technical team has plastic technology basic competence certification, junior injection molding engineers, intermediate injection molding engineers, and material application engineer, and can provide the best material selection and processing technology according to customer needs:

- Material selection suggestions - Provide the most suitable plastic materials according to product use

- Appropriate mold development - Reasonable mold development based on product needs to avoid mold costs being too high or not meeting their service life.

- Special functional plastic development - Provide customized materials such as anti-ultraviolet, anti-aging, and anti-static

- High-precision injection molding technology - Ensure that products meet high quality, high precision, and high-performance standards

The selection of plastic materials not only affects product performance, but also production costs and market competitiveness. Yeh Her Yow plastic Co., Ltd. ensures that every product meets the highest quality and market demand through professional material analysis, precision mold development, precision injection technology, and intelligent manufacturing processes.

Core Advantages of Yeh Her Yow plastic Co., Ltd.

- Professional Certification and Technical Team

Our technical team has professional qualifications such as plastic technology basic ability certification, junior injection molding engineer and intermediate injection molding engineer and material application engineer. They master material selection and characteristic analysis, mold design and manufacturing, injection molding parameter adjustment and quality management, and mass production process optimization. Our professional technology ensures product accuracy and stability and provides customers with the best solutions.

- One-stop integrated service

We provide product design, mold development, injection manufacturing, quality inspection, post-processing and assembly to ensure that all stages are seamlessly connected, allowing customers to enjoy an efficient manufacturing experience.

- Precision mold development

Work closely with the Plastic Industry Development Center to ensure that the mold design meets the standards of high precision, high durability and low maintenance, and provide customers with the best manufacturing solutions.

- Advanced material application

We use a variety of plastic materials such as ABS, PP, PE, PC, PA, POM, etc., and adjust material selection and process parameters according to customer needs to ensure that the product achieves optimal performance.

- Smart manufacturing and quality control

We use smart production technology to improve production efficiency and quality stability through data analysis and automated equipment.

The unique value of Yeh Her Yow plastic Co., Ltd.

✔ The unique value of Yeh Her Yow plastic Co., Ltd.

✔ Comprehensive services – one-stop integrated services to reduce development costs and production time

✔ Stable quality – strictly control each process to ensure that the product meets the standards

✔ Strong customization capabilities – provide material selection and mold design according to customer needs