What is Plastic Injection Molding? A Comprehensive Analysis of Injection Molding Technology

What is Plastic Injection Molding?

Plastic injection molding is a modern, high-efficiency and precision manufacturing technology that transforms various plastic materials through melting, injection, and cooling into products with different shapes and structures. This process is widely used in industries such as electronics, automotive parts, household products, and medical equipment. Additionally, when using high-performance engineering plastics, it can be applied to specialized industries like aerospace, military, and semiconductor manufacturing.

Key Advantages of Plastic Injection Molding:

High Precision

Enables the production of complex structural components. Compared to metal processing, which requires multiple steps and high costs, plastic injection molding can manufacture intricate parts in a single well-designed injection process, significantly reducing time and expenses.

High-Efficiency Production

Ideal for mass production, ensuring product consistency. With rapid technological advancements, efficient production is key to cost reduction. Depending on the wall thickness and complexity, most injection molding cycles take around 40 to 120 seconds, offering faster and more economical mass production compared to other processing methods. With properly designed molds and optimized injection parameters, dimensional accuracy can be maintained within acceptable tolerances, ensuring seamless assembly and functional reliability.

Material Versatility

Allows selection of materials such as ABS, PP, PE, PC, covering commodity plastics, engineering plastics, and high-performance plastics. Materials can be tailored for different application environments, including UV resistance, light stabilization, aging resistance, oxidation resistance, reinforcement fillers, UL94 fire resistance, anti-static properties, and conductivity.

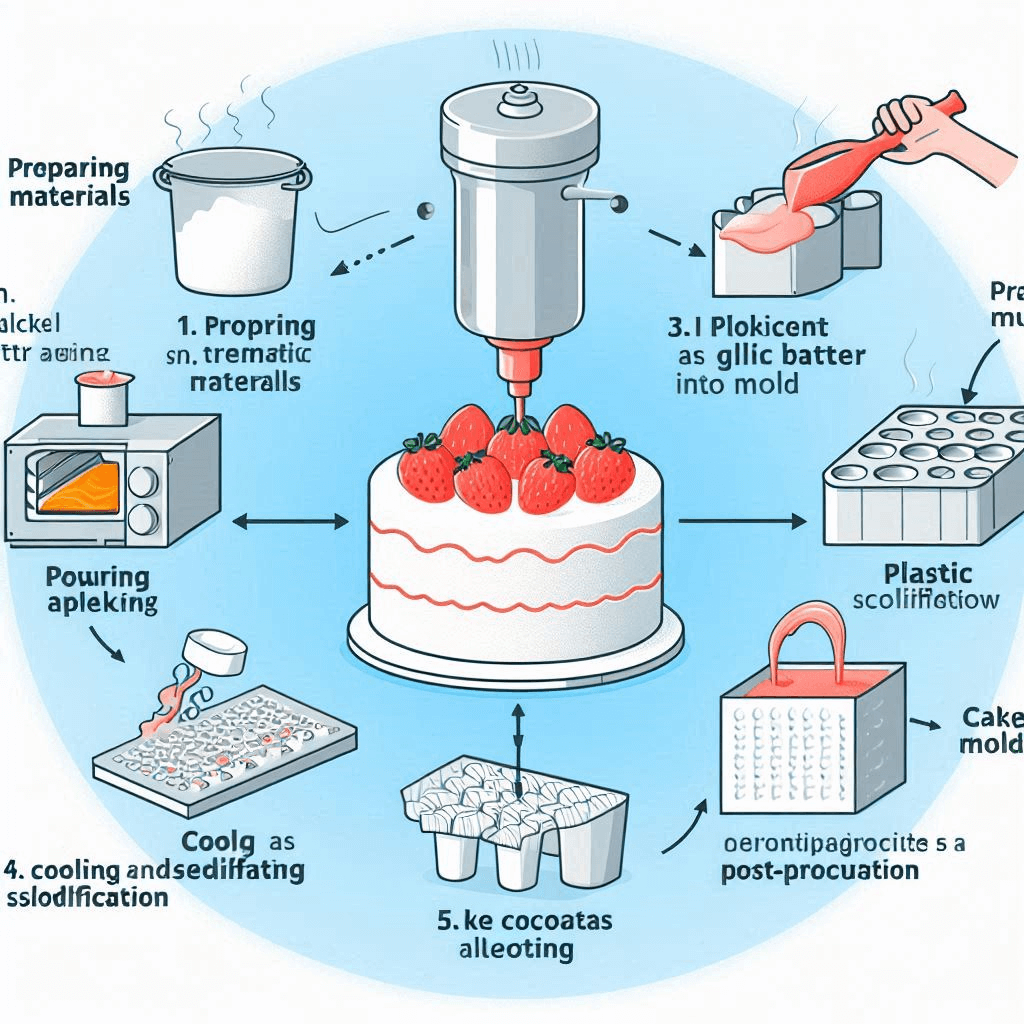

Explaining Injection Molding Through Everyday Examples

Imagine making a cake:

- Preparing Materials –

You need flour, eggs, and butter, similar to the raw materials in plastic injection molding. - Heating and Mixing –

Ingredients are blended and heated in an oven, analogous to plastic melting, which turns solid granules into a flowable state. - Pouring into a Mold –

Cake batter is poured into a mold, just like injecting molten plastic into a mold cavity. - Cooling and Solidification –

The baked cake cools and hardens, similar to how plastic solidifies inside a mold. - Removing from the Mold and Decorating – The cake is taken out and decorated, resembling the post-processing of a molded plastic product.

This simple analogy helps illustrate the plastic injection molding process, showing how raw materials are transformed into precisely shaped and high-quality products!

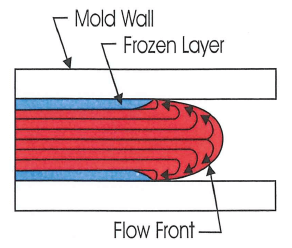

The flow behavior of plastic follows the characteristics of a non-Newtonian fluid, filling the mold cavity in a fountain flow pattern

Technical Details of Injection Molding

Plastic injection molding is a high-efficiency, precision manufacturing method that involves the following steps:

- Raw Material Preparation –

Selection of ABS, PP, PE, PC, PA, and other materials. The plastic is dried using hot air dryers, honeycomb desiccant dryers, or vacuum dryers to maintain appropriate moisture levels and ensure processing quality. - Melting and Heating –

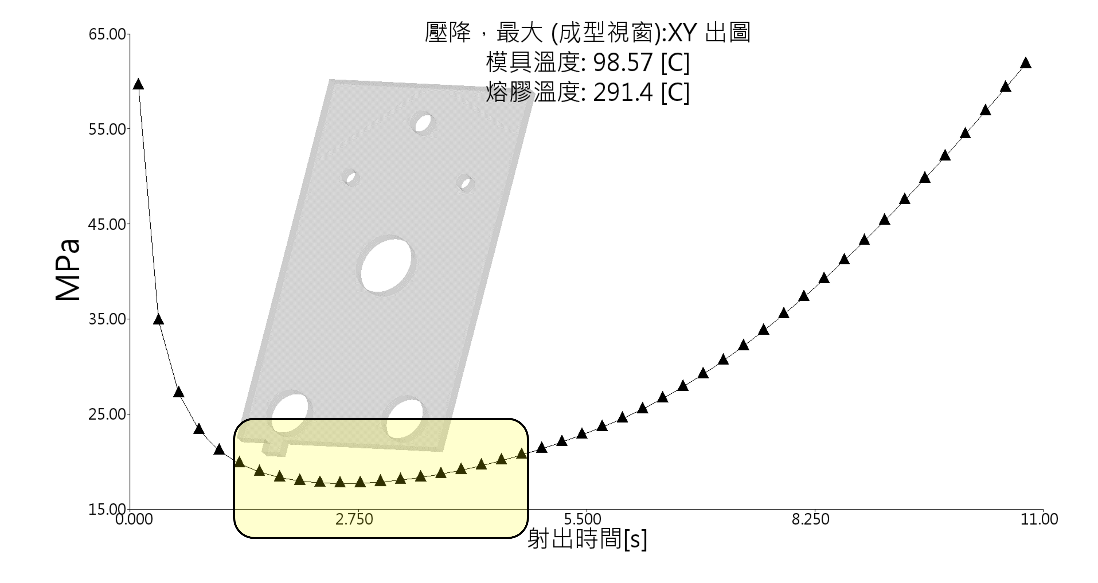

The injection unit heats plastic granules to an optimal melt viscosity while ensuring uniform mixing. Moisture and trapped air are eliminated to maintain consistency. If color blending is required, uniformity must also be ensured. - High-Pressure Injection –

Molten plastic is injected under high pressure into the mold cavity via well-designed flow channels, including sprues, main runners, sub-runners, and gates, ensuring even material distribution. Injection speed and pressure directly affect the final product's quality.

Molten plastic is injected under high pressure into the mold cavity via well-designed flow channels, including sprues, main runners, sub-runners, and gates, ensuring even material distribution. Injection speed and pressure directly affect the final product's quality.

- Packing and Cooling – As plastic fills the mold, packing pressure is applied based on the projected area of the part. The mold cavity can sustain tens, hundreds, or even thousands of tons of pressure to ensure dimensional accuracy. The optimized cooling system in the mold helps solidify the plastic efficiently.

- Ejection and Quality Inspection –

nce the mold opens, the ejection system or hydraulic core pullers release the product. It is then removed manually or using robotic arms, followed by appearance checks and precise measurements to ensure it meets specifications.

- Post-Processing and Assembly –

Some products require secondary or tertiary processing, including polishing, painting, laser engraving, printing, heat transfer, or assembly, to enhance functionality and aesthetics.

This advanced manufacturing process is widely applied in automotive parts, electronic enclosures, household products, and medical equipment, becoming a key technology in modern industrial production due to its high precision, efficiency, and scalability.

Key Factors for High-Efficiency Production

How to Improve Production Efficiency? Choose Yeh Her Yow plastic Co., Ltd.

At Yeh Her Yow plastic Co., Ltd., we enhance plastic injection molding efficiency with the following technologies:

High-efficiency production is not just about quantity, but also about maintaining quality and cost balance. By leveraging technological innovations and smart manufacturing, we ensure that every batch of products meets the highest standards of quality and efficiency.

If you are looking to optimize your production process, we can provide customized solutions tailored to your needs—feel free to contact us!

This translation preserves your original technical details and formatting, making it easy to integrate into your website while maintaining clarity for an international audience. If you need further refinements, additional technical explanations, or specialized industry terminology, let me know, and I’ll be happy to assist!

Core Advantages of Y.H.Y.

1. Professional Certification & Technical Team

Our technical team holds Plastic Technology Basic Competency Certification, Junior Injection Molding Engineer, and Intermediate Injection Molding Engineer qualifications (The highest-level injection molding certification currently available in Taiwan), ensuring expertise in:

Our specialized skills guarantee precision and stability, delivering the highest-quality solutions to our clients.

2. One-Stop Integrated Service

We provide product design, mold development, injection molding, quality inspection, post-processing, and assembly, ensuring seamless coordination across all manufacturing stages for a highly efficient production experience.

3. High-Precision Mold Development

We collaborate closely with the Plastics Industry Development Center, ensuring our molds are designed for high precision, long durability, and low maintenance, providing the best manufacturing solutions for our clients.

4. Advanced Material Applications

We utilize ABS, PP, PE, PC, PA, POM, and various other plastics, tailoring material selection and processing parameters to meet specific customer needs and ensure optimal product performance.

5. Smart Manufacturing & Quality Monitoring

We integrate intelligent production technologies and utilize data analytics & automated systems to improve production efficiency and maintain product quality stability.

Unique Value of YEH HER YOW PLASTIC CO., LTD.

This translation maintains the original clarity, precision, and structured layout, ensuring it is ready for website integration or business presentations. Let me know if you need further refinements, industry-specific terminology adjustments, or additional details!