Combination of plastic and aluminum alloy (2)

Combination concept of plastic and aluminum alloy

Plastics are often used together with aluminum or aluminum alloys, whether using aluminum as a structural support, or using aluminum as an internal heat dissipation material, or using aluminum alloy as an exterior, as a decorative product, in The combination of plastic and aluminum inevitably requires locking and co-molding. In terms of the characteristics of two different materials, one is an inorganic material and the other is an organic material. There are great differences in physical properties. In combination, thermal environmental factors need to be taken into consideration. Different materials will face different factors of expansion and contraction due to their own heating or the influence of external ambient temperature.

Thermal expansion and contraction

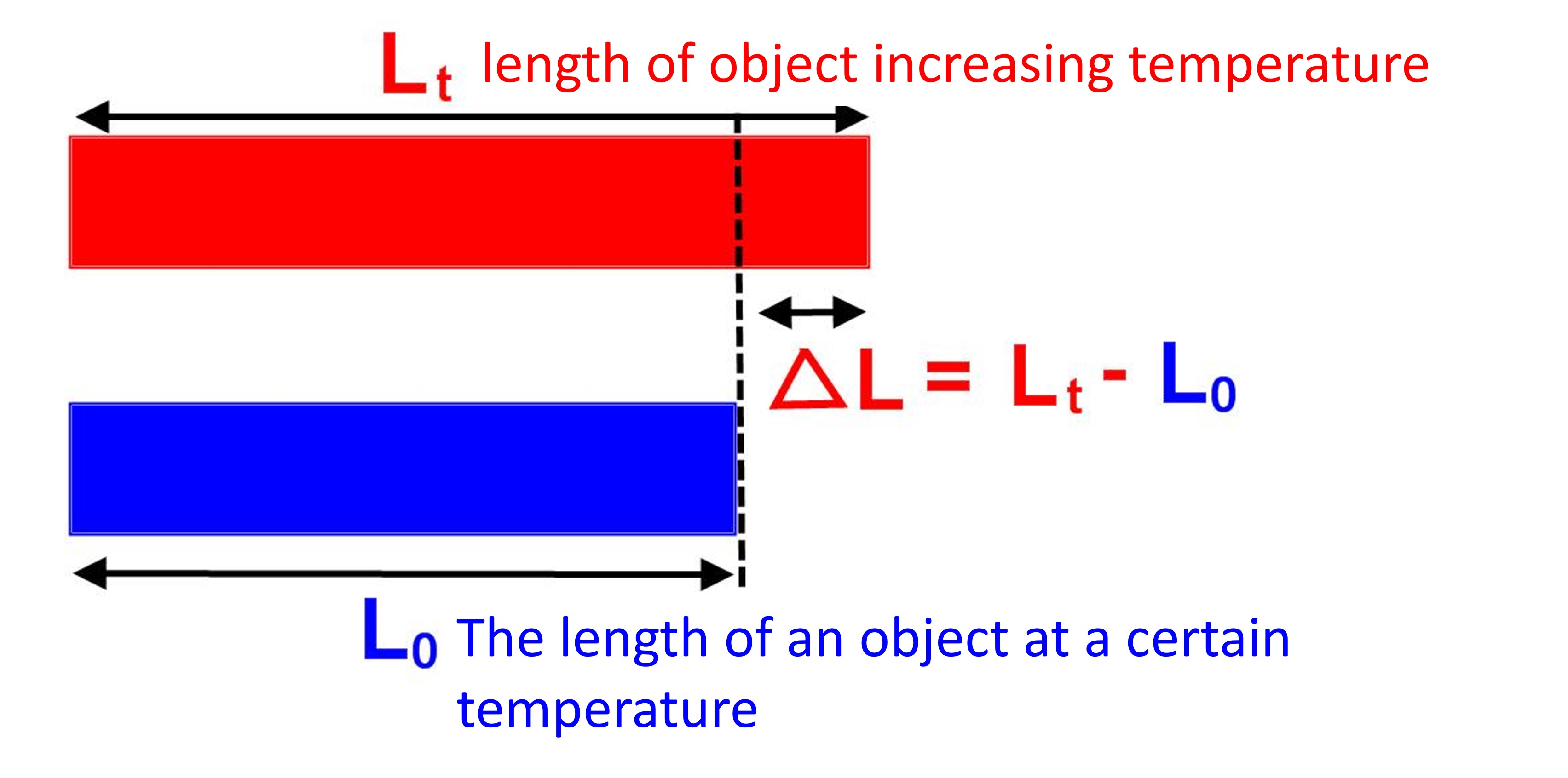

Generally speaking, when a substance is heated, it is under the effect of thermal expansion and contraction, and the geometric properties of the substance itself, such as length, area or volume, will change with the change of temperature. Thermal expansion and contraction refer to the characteristic that an object expands when it is heated and contracts when it is cold, and its shape, volume, and density may change accordingly. Since the average kinetic energy of particles in an object is an increasing function of temperature, when the temperature rises, the vibration amplitude of the particles increases, causing the object to expand; but when the temperature drops, the vibration amplitude of the particles decreases, causing the object to shrink. . If the temperature difference does not change much, the percentage increase of the length of the one-dimensional object will be proportional to the temperature difference, and its proportional coefficient is called the linear expansion coefficient. More specifically, the so-called coefficient of linear expansion refers to the ratio of the change in length of a solid to its length at the original temperature when the temperature changes by 1 degree Celsius.

Coefficient of linear expansion/coefficient of thermal expansion

Under most normal circumstances, the linear expansion coefficient is positive, but there are exceptions, such as water between 0 and 4 ° C, there will be anti-expansion phenomenon, or some ceramic materials will change when the temperature rises. The amount is extremely small, and its linear thermal expansion coefficient is close to 0. Linear expansion can be seen everywhere in daily life applications. For example, gaps are left in the design of rail joints and bridge joints to avoid the danger of bending caused by thermal expansion.

Design considerations

In terms of product design, it is not simply a one-dimensional length concept. Product design is a three-dimensional facet. Factors to be considered need to include temperature factors such as production environment, transportation environment, and use environment. How to incorporate more comprehensively into the design The consideration will affect the strength and life cycle of the actual use of the product in the future.

In the table below, it can be seen that although the same plastic material is used, the expansion coefficients that need to be considered are different when using different materials. How to cover a wider range of design concepts in product development, Yeh Her Yow Company can assist in joint product development.

| Material | Thermal expansion coefficient 10-5cm/cm/℃ |

| Normal glass | 0.7 |

| Industrial glass | 0.5 |

| Steel | 1.1 |

| Stainless Steel | 1.5 |

| Concrete | 1.4 |

| Brass | 1.8 |

| Aluminum | 2.3 |

| Wood | 0.8 |

| PEI/GF | 2.3 |

| PA/GF | 2.3 |

| PBT/GF | 2.5 |

| PC/GF | 2.8 |

| ABS/GF | 3.1 |

| PP/GF | 3.2 |

| PPS | 3.6 |

| POM/GF | 4.0 |

| PS | 5.4 |

| PC/GF | 6.5 |

| ABS | 7.2 |

| PVC | 8.0 |

| PMMA | 8.5 |

| PA | 8.1 |

| POM | 8.5 |

| PBT | 8.6 |

| PP | 12.1 |

| PE | 14.5 |